Process integration

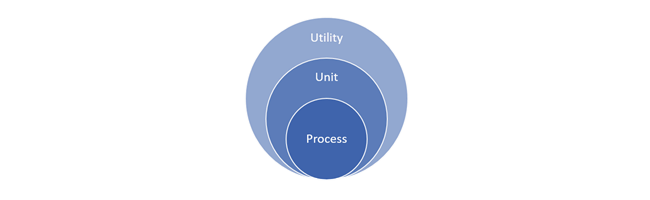

High-temperature heat pumps may be integrated at a variety of levels, such as the process level, the unit level or the utility level. The selection of the level of integration is a crucial decision with respect to both operating performances and investment cost and is impacted by various parameters.

Heat pumps may be integrated at different levels of integration with production processes, such as:

- Process level

- Unit level

- Utility level

In addition to these, also combinations of centralized and decentralized systems are possible.

The heat pump placement is impacting various relevant parameters and finding the optimal placement is thereby a crucial aspect for the feasibility of heat pump projects. Some of the parameters impacted by the level of integration are:

- Operating performance (higher for integration at process level - lower at utility level)

- Required scope of modifications (typically higher for integration at utility level)

- Impact on the production process (higher for integration at process level)

- Implementation process (long term conversion strategy or one-time overhaul)

Finding the optimal integration scenario is in turn dependent on various parameters, including:

- Current system layout

- Characteristics and dimensions of existing parameters

- Required replacements of existing components

- Availability, location, and simultaneity of heat sources

It becomes apparent that the process integration of the heat pump is a challenging aspect with a decisive impact on the overall feasibility of the project. In this project, WP 2 is intended to study this aspect in detail and to develop methods and procedures for supporting the process integration. The activities aim to identify the main barriers and derive conversion strategies in order to support the integration process.