What is a High-Temperature Heat Pump?

No clue what a heat pump is and how it can supply high-temperature process heat? Get an overview here!

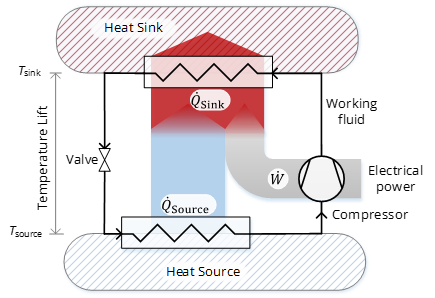

The basic heat pump process

A heat pump is a device that moves heat from a certain temperature to a higher temperature by adding electrical power. Thereby, heat is recovered from an unusable temperature to a temperature where it it is useful, e.g. for process heating or any other application. Often, industrial heat pumps are recovering excess heat from the same process as they are supplying to. In this case, both the heating demand and the cooling demand of a process can be covered, and performances get very high.

The heat from the heat source and the supplied power add up to the amount of heat which is supplied to the heat sink. The power which is used for upgrading the heat is only a fraction of the supplied heat, enabling two to five units of heat to be supplied per unit of consumed power. In some applications, the performances get even higher. This ratio is referred to as the Coefficient of Performance (COP), which is usually used for characterizing the performance of a heat pump. The maximum achievable COP is dependent on the temperatures of the heat source and the heat sink, while the highest COPs may be reached for low temperature lifts. However, the higher the temperature lift, the higher the amount of power which has to be invested for upgrading - and accordingly the lower is the COP. Keeping this in mind, it becomes apparent why it is important to keep temperature differences low and match the temperature profiles of the secondary fluids.

The heat from the heat source and the supplied power add up to the amount of heat which is supplied to the heat sink. The power which is used for upgrading the heat is only a fraction of the supplied heat, enabling two to five units of heat to be supplied per unit of consumed power. In some applications, the performances get even higher. This ratio is referred to as the Coefficient of Performance (COP), which is usually used for characterizing the performance of a heat pump. The maximum achievable COP is dependent on the temperatures of the heat source and the heat sink, while the highest COPs may be reached for low temperature lifts. However, the higher the temperature lift, the higher the amount of power which has to be invested for upgrading - and accordingly the lower is the COP. Keeping this in mind, it becomes apparent why it is important to keep temperature differences low and match the temperature profiles of the secondary fluids.

Systems and components

The simple layout of an electrically driven vapor compression heat pump consists of a compressor and an expansion valve working in between an evaporator and a condenser. These components represent a closed cycle, and a working fluid is circulated within the cycle. In the evaporator, heat is retrieved from the environment and transferred to the working fluid, which evaporates. The evaporated working fluid is compressed, while both pressure and temperature increase. At higher pressures, the working fluid is circulated through the condenser, where it condenses, while the heat is transferred to the heat sink. The condensed working fluid is expanded in a valve, before it reenters the evaporator at a lower pressure.

The fluid properties of the selected working fluids have an impact on the design of the cycle, the components, and the overall efficiencies of the cycle. In order to optimize the cycle performance and reach the highest efficiencies for a given application, an overall optimal combination of the working fluid, the cycle layout, and the components has to be found.

High-temperature applications

Industrial heat pumps are mainly applied in applications with lower forward temperatures. The majority of industrial heat pumps is based on conventional refrigeration technology, which means operating at higher temperatures and pressures. Instead of lifting heat from the cooling temperature to the ambient, heat pumps upgrade heat from the ambient (or higher) to the required process heat temperature. Besides the higher efficiencies at lower temperatures, it may be noted that conventional ammonia systems may be operated with supply temperatures of up to 90 °C with only minor modifications.

However, technological developments and more beneficial economic boundary conditions increase the competitiveness of high-temperature heat pumps and allow for economically feasible process heat supply at temperatures even above 100 °C. Heat pumps are commonly considered as high-temperature heat pumps when operating with supply temperatures above 100 °C.